Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

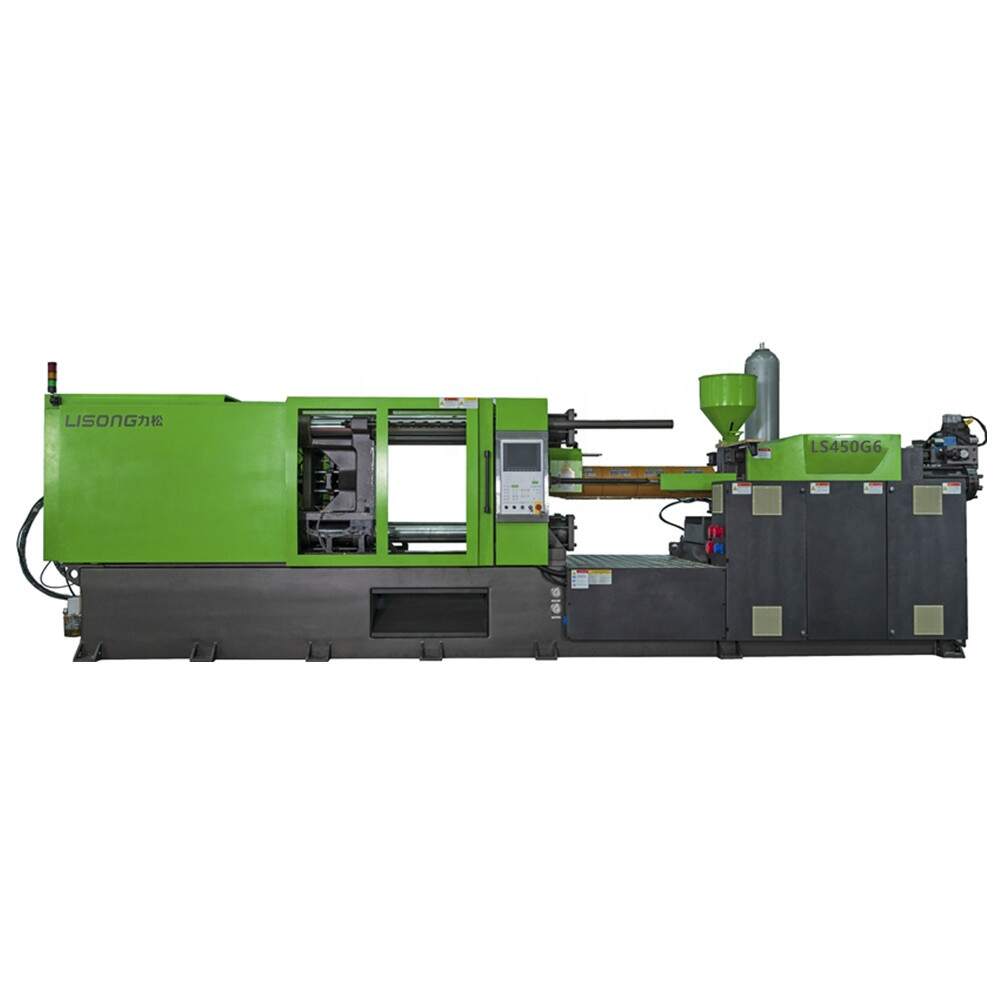

Plastic Injection Moulding Machine Manufacturer

Latest Blog

Servo injection mold machine Supplier Factory

Introduction

In the dynamic world of plastic manufacturing, servo injection mold machines represent a significant leap forward in technology and efficiency. These machines, driven by servo motors, have transformed traditional injection molding processes, offering unparalleled precision, energy efficiency, and reliability.

Understanding Servo Injection Mold Machines

Servo injection molding machines utilize servo motors for various movements during the molding process, including injection, mold closing, and cooling. These motors are known for their precise control and speed, leading to more accurate and consistent product output.

Design and Technological Advancements

High Precision Control

- Servo motors provide precise control over the injection molding process, ensuring consistent product quality.

- Improved repeatability is achieved through exact control of pressure, speed, and position.

Energy Efficiency

- These machines consume significantly less energy compared to traditional hydraulic injection molders, reducing operational costs.

- Energy savings are achieved by the ability of servo motors to consume power only when needed during the molding process.

Reduced Noise and Emissions

- Servo injection mold machines operate with less noise, creating a more comfortable working environment.

- Lower emissions make them a more environmentally friendly option in the manufacturing industry.

Applications in Various Industries

Servo injection mold machines are versatile and can be used in a wide range of industries, including automotive, consumer electronics, medical equipment, and packaging. Their ability to produce complex and high-precision parts makes them ideal for advanced manufacturing requirements.

The Benefits of Servo Injection Mold Machines

- Enhanced Product Quality: Improved precision and repeatability lead to higher-quality products.

- Cost Efficiency: Lower energy consumption translates into cost savings in the long term.

- Faster Cycle Times: Increased efficiency in operation speeds up production cycles.

- Environmental Friendliness: Reduced energy consumption and emissions contribute to sustainable manufacturing practices.

The Core of Servo Injection Mold Machine Factories

A servo injection mold machine supplier factory is essentially a hub of technological advancement, where the focus is on designing, producing, and distributing high-quality servo-driven injection molding machines. These factories are equipped with the latest manufacturing technologies and are staffed by skilled professionals.

Key Features of Servo Injection Mold Machine Factories

Advanced Manufacturing Facilities

- State-of-the-art production lines designed for the assembly and testing of servo injection mold machines.

- Utilization of precision engineering to ensure the high accuracy of machine components.

Research and Development (R&D)

- Dedicated R&D teams working on innovative solutions to enhance machine performance and energy efficiency.

- Continuous improvement of machine designs to meet evolving market demands and technological trends.

Quality Control and Assurance

- Rigorous quality control measures at every stage of production to ensure reliability and performance.

- Adherence to international quality standards and certifications.

Benefits of Partnering with a Servo Injection Mold Machine Supplier Factory

Access to Latest Technology

- Clients benefit from the latest advancements in servo injection molding technology.

- Customization options to tailor machines to specific industrial needs.

Enhanced Production Capabilities

- Improved product quality and consistency due to the precision of servo machines.

- Increased production efficiency with reduced cycle times and energy consumption.

After-Sales Support and Services

- Comprehensive after-sales services, including installation, training, and maintenance.

- Availability of spare parts and technical support to ensure uninterrupted operation.

Eco-Friendly Manufacturing Solutions

- Reduction in energy consumption and carbon footprint, aligning with sustainable manufacturing practices.

- Compliance with environmental regulations and standards.

Conclusion

Servo injection mold machine supplier factories are more than just production sites; they are catalysts for innovation in the manufacturing sector. By providing advanced, energy-efficient, and precise machines, these factories empower industries to meet the challenges of modern manufacturing. Their commitment to quality, sustainability, and continuous improvement positions them as key players in driving industrial growth and technological progress.