Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

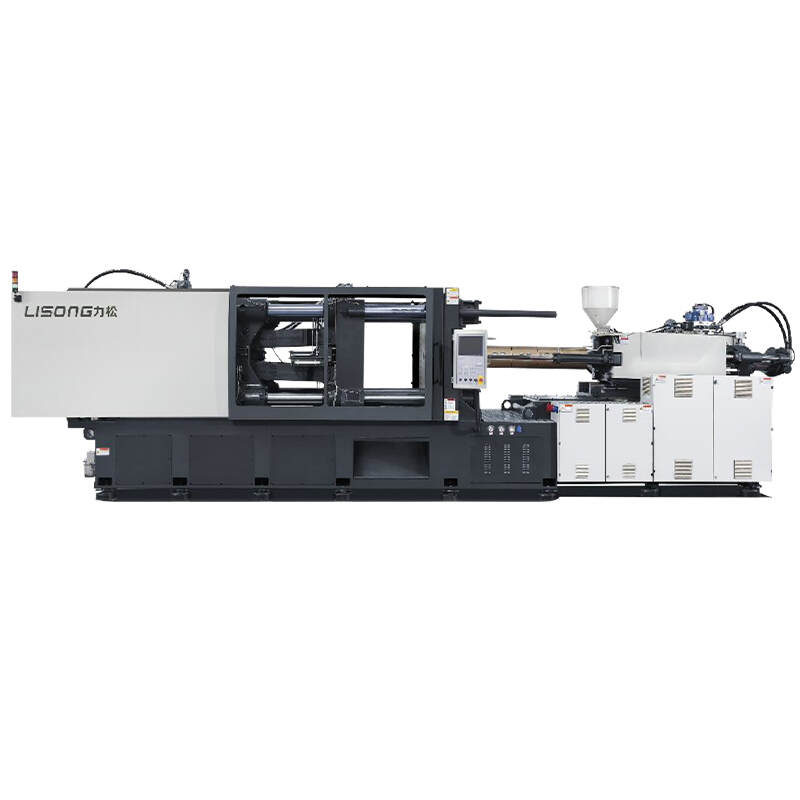

China Medical/PET/Plastic Injection Machine Supplier Factory Manufacturer

LISONG, the esteemed Medical, PET, and Plastic Injection Machine Supplier, Factory, and Manufacturer in China, offers a comprehensive range of high-quality, customizable machinery that meets the diverse needs of businesses across various industries.

Packaging Series

(11)FOOD CONTAINER INJECTION MACHINE

Food container injection molding machine is an intelligent equipment for producing food containers. The machine adopts the double-layer opening and closing ring structure of air tight sealing ring, which can create a waterproof and airtight full-automatic injection molding machine environment for the production of seamless injection molding products such as children's food, frozen food and ice cream cartons.

PLASTIC DISPOSABLE CULTURE DISH MAKING MACHINE

Plastic disposable culture dish making machine for producing disposable culture dishes, single samples, cups or any other plastic products. It is a high-quality, high-performance machine. Fully automatic, easy to operate and maintain. Our machines are manufactured to strict standards to ensure product reliability.

THIN WALL FOOD CONTAINER MACHINE

Thin wall food container machine is used to produce vacuum food packaging machine, which can package microwave oven, refrigerator and frozen food packaging. Our thin-walled food container machines are uniquely designed and manufactured. With the characteristics of high efficiency, low energy consumption and convenient operation and maintenance, it has won high praise from domestic users.

PLASTIC FOOD PACKAGING CONTAINER MAKING MACHINE

Plastic packaging container manufacturing machine is an advanced production line with simple structure, reasonable design and clear appearance. This machine can produce all kinds of plastic products, such as bean cans, seasoning cans, syrup bottles, seasoning bottles, etc.

Bucket Series

(6)PP INJECTION MACHINE

PP injection machine is a kind of injection molding plastic parts designed for injection molding of PP, PE, PVC. Mix the plastic raw materials, adjust the heating furnace to the required temperature, and inject the plastic materials into the mold cavity to mix. Molten plastic pellets are evenly distributed in the mold cavity through flow channels created by core pins or gating tools. After cooling, high-strength, high-density, high-quality plastic products can be obtained.

BUCKET INJECTION MACHINE

Bucket injection machine inject plastic, glass or metal barrels into the seal. Using standard nozzles allows mixing of different colors and materials, providing mixed color matching capabilities for products. Equipped with a control panel and a safety stop to prevent infusion spillage.

BUCKET PAIL INJECTION MOLDING MACHINE

Bucket pail injection molding machine is used for injection molding production of preparation barrels, barrels, plastic cups and other containers. The main working parts are hollow plunger rods and reinforcing frames. The hollow plunger rod and the steel rod are firmly welded together through high-pressure heat treatment (diamond welding process), with high impact strength.

PAILS INJECTION MACHINE

The pails injection machine can provide more than 25 kinds of materials with different patterns on one bottle at the same time. The applied technology can save raw materials to a great extent and achieve higher output in a shorter time.

Basket

(5)BASKET MAKING INJECTION MACHINE

The basket making injection machine is designed for making various lightweight baskets such as straw and paper, and is suitable for general injection molds and plastic products. It can produce brush nets, safety belts, safety nets, sporting goods and other pet products. 3D parts can be made by low-temperature curing injection molding of PUR foam, ordinary foam, closed-cell foam, and sealant.

FRUIT PACKAGING BOX INJECTION MACHINE

The fruit packing box injection machine automatically injects hot melt adhesive into four trays to form a complete fruit packing. This machine is equipped with a five position automatic feeding system, which can be used with other packaging machines or as an independent packaging system. It is an ideal equipment for large supermarkets and chain retailers to make fruit bags of different sizes, shapes and quantities.

WASTE BIN INJECTION MACHINE

The waste bin injection machine is used to inject waste plastic into empty food packaging materials. The whole production line is composed of main machine, auxiliary machine and energy (mainly electric energy). The main working principle is to use the reciprocating cutter to cut the garbage can into a certain thickness and width, and then press it down by the sliding blade to get the finished product.

URINE SPECIMEN CUP MAKING MACHINE

The urine specimen cup making machine is used to manufacture single-use collection containers, designed to produce an accurate number of sample cups with high-quality permanent labels in a short period of time. Used to collect and transport biomedical samples from hospitals/laboratories, purify urine samples for drug testing.