Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

Packaging Series

Packaging Series

(11)LISONG's journey in the plastic packaging machinery sector spans several decades, reflecting a profound legacy of industry expertise. This wealth of experience has enabled them to stay at the forefront of emerging market trends, technological advancements, and evolving customer needs. LISONG's deep-rooted knowledge is the bedrock upon which they develop pioneering solutions for their clients.

- Comprehensive Product Range:

LISONG takes pride in offering an extensive and versatile product portfolio that caters to a wide spectrum of industries and applications. Whether in the food, pharmaceuticals, cosmetics, or any other sector, customers can find tailored packaging solutions that meet their precise requirements.

Key Product Categories:

- Injection Molding Machines

- Blow Molding Machines

- PET Preform Machines

- Plastic Auxiliary Equipment

- And more...

- Cutting-Edge Technology:

Innovation is at the heart of LISONG's operations. They consistently invest in research and development to incorporate the latest technological breakthroughs into their machinery. This unwavering commitment to innovation ensures that their customers benefit from state-of-the-art packaging solutions that optimize efficiency and reduce operational costs.

- Rigorous Quality Control:

Quality is a non-negotiable aspect of LISONG's manufacturing process. Their production facilities adhere to stringent quality control standards, ensuring that each machine leaving their premises meets the highest industry benchmarks. This dedication to quality has earned them numerous certifications and accolades, establishing LISONG as a trusted provider of packaging solutions.

- Global Reach:

LISONG has a formidable global presence, serving customers in countless countries worldwide. Their extensive network of distributors and service centers guarantees that clients receive timely support and maintenance services, regardless of their geographical location. This global outreach underlines LISONG's steadfast commitment to customer satisfaction.

- Customer-Centric Approach:

At LISONG, the customer always comes first. They work closely with clients to gain a deep understanding of their unique packaging challenges and then provide customized solutions that effectively address these challenges. This customer-centric approach has earned them a loyal and satisfied customer base.

FOOD CONTAINER INJECTION MACHINE

Food container injection molding machine is an intelligent equipment for producing food containers. The machine adopts the double-layer opening and closing ring structure of air tight sealing ring, which can create a waterproof and airtight full-automatic injection molding machine environment for the production of seamless injection molding products such as children's food, frozen food and ice cream cartons.

PLASTIC DISPOSABLE CULTURE DISH MAKING MACHINE

Plastic disposable culture dish making machine for producing disposable culture dishes, single samples, cups or any other plastic products. It is a high-quality, high-performance machine. Fully automatic, easy to operate and maintain. Our machines are manufactured to strict standards to ensure product reliability.

THIN WALL FOOD CONTAINER MACHINE

Thin wall food container machine is used to produce vacuum food packaging machine, which can package microwave oven, refrigerator and frozen food packaging. Our thin-walled food container machines are uniquely designed and manufactured. With the characteristics of high efficiency, low energy consumption and convenient operation and maintenance, it has won high praise from domestic users.

PLASTIC FOOD PACKAGING CONTAINER MAKING MACHINE

Plastic packaging container manufacturing machine is an advanced production line with simple structure, reasonable design and clear appearance. This machine can produce all kinds of plastic products, such as bean cans, seasoning cans, syrup bottles, seasoning bottles, etc.

CUP INJECTION MACHINE

This cup filling machine is used to fill the contents of different plastic packages, such as bottles and cups. To use the machine, you need to place a suitable plastic container on a threaded screw that is screwed into the top of the filling hopper. Next, you open the clamping plate on the cylinder head so that water pressure can push the plastic into the bottle. Once all containers are full, you can close the splint and then rotate it counterclockwise to remove it from the filling head.

FORK INJECTION MACHINE

Fork injection machines can be divided into linear and rotary. The former generally adopts the rebound type, while the latter is more widely used. The working process of the machine is to use the piston to inject the raw material into the mold of the plastic product, and the processing material heater melts and cools and solidifies to make it shape.

HIGH SPEED THIN WALL PRODUCTS MACHINE

The high-speed thin-wall product machine provides customers with the most advanced and reliable machine, which is suitable for producing high-speed automatic production lines of different sizes, such as paper cup covers, plastic cup covers, glass bottles, candy packaging paper, etc. High speed thin-walled product machine is a new type of precision die design and manufacturing equipment.

SPOON INJECTION MACHINE

The spoon injection molding machine is a fully automatic plastic spoon injection molding machine, which is used for the injection of PP, PE and other plastics and rubber. Produce different kinds of plastic products, such as spoon handles, spoons, etc., by changing the mold type.

PLASTIC MOLD DISPOSABLE SPOON

Disposable spoon plastic mold is the most effective and convenient way to make disposable spoons. The production cost is low and the quality is high. The tool is the ideal way to make the perfect plastic spoon quickly! Just pour the liquid into the plastic mold and wait for it to harden. Compatible with any liquid detergent and very easy to use. It's possible to make your own disposable spoons without any extra help.

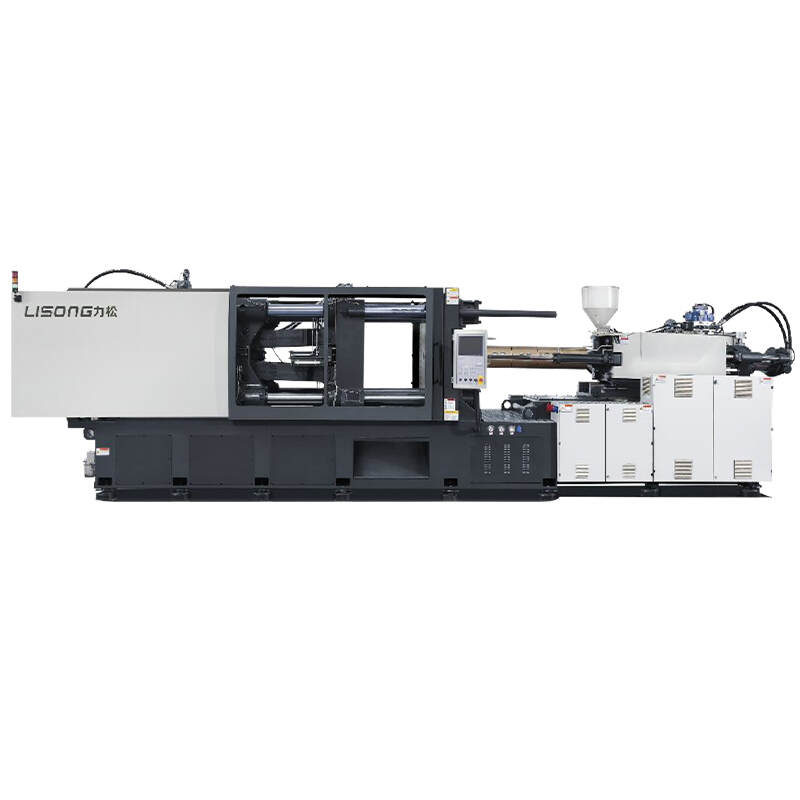

PLASTIC INJECTION MOLDING MACHINE

Injection molding machine - injection molding machine is the main equipment used to perform various plastic processing processes. Polymer manufacturing process usually involves many different machines, which play different roles in injection molding technology. It mainly includes injection molding machine, extruder, heating system, cooling system and metering pump.

THIN WALL INJECTION MACHINE

Thin wall injection machine is a kind of machinery for soft packaging food. It is mainly used to fill the raw materials with the forming mold, and then inject them into the jar or bottle. It is widely used in high-grade vinegar, ketchup, jam and other industries.