Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

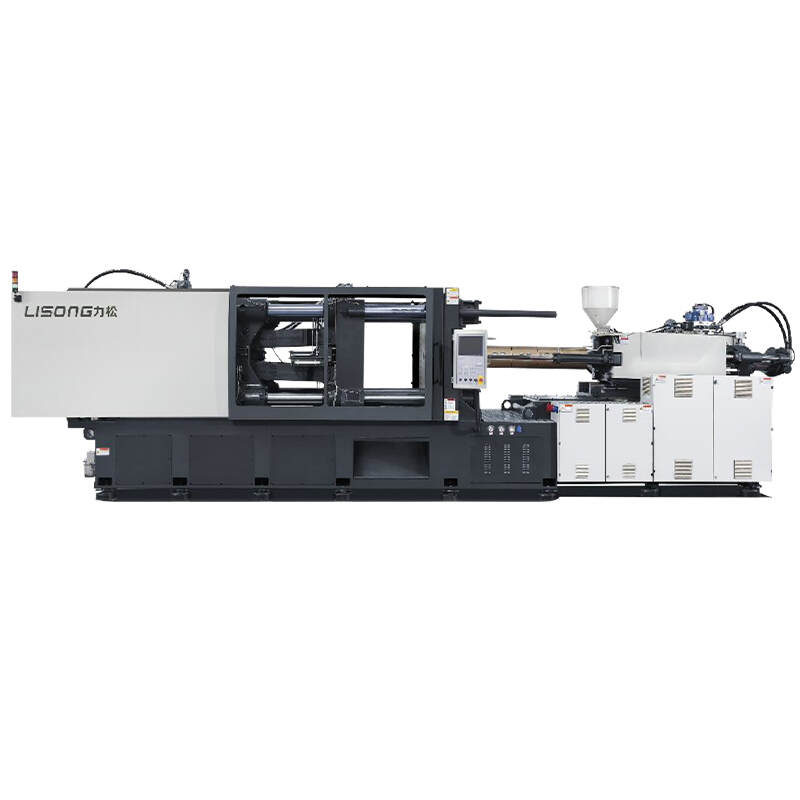

China Medical/PET/Plastic Injection Machine Supplier Factory Manufacturer

LISONG, the esteemed Medical, PET, and Plastic Injection Machine Supplier, Factory, and Manufacturer in China, offers a comprehensive range of high-quality, customizable machinery that meets the diverse needs of businesses across various industries.

Medical Series

(6)MEDICAL NEEDLE MAKING MACHINE

Medical needle making machine is used to produce different kinds of medical needles, such as safety needles and skin puncture needles. The medical needle making machine is specially designed for the production of various types of medical needles, such as subcutaneous injection needles and intravenous injection needles, with high precision and convenient operation. It can be widely used in hospitals, medical device factories and other institutions producing medical needles.

INJECTION MACHINE MEDICAL SYRINGE PRODUCTION

The medical syringe injection machine is applicable to drugs, serum, liquid and slurry substances. Various types of medical syringe moulds can be used. The production process is simple, convenient and highly automated. It can be used to manufacture more than 100 kinds of medical syringes without defects of raw materials such as manual or injection molding machine. Injection molding machine is a professional manufacturer of medical syringes, which can produce various specifications of plastic syringes.

INJECTION PLANT MACHINE MEDICAL EQUIPMENTS

The injection machine is a device designed to inject substances into appropriate cavities of the body with very high accuracy. It is mainly used for injection in dermatology and plastic surgery, internal medicine and oncology, orthopedics, dentistry and endoscopy.

MEDICAL DISPOSABLE PRODUCTION INJECTION MACHINE

Medical injection machine is a kind of medical equipment that can automatically inject liquid medicine into the human body. It can connect the whole medical system of hospitals and clinics for medical treatment. High precision and high speed; Compact design, light weight, easy to move.

PET Preform Series

(7)PLASTIC MACHINE FOR PREFORM BOTTLE

The preform bottle forming machine is used to process preforms. The machine is made of high-quality stainless steel and manufactured in strict accordance with production standards. It has advanced equipment and technology, and is driven by imported rubber wheel motors, which can be mass-produced.Used in cosmetics and food packaging, pharmaceuticals and condiments, durable goods and transportation lines, pesticides and other industries.

PET PREFORM MAKING INJECTION MACHINE

PET preform making injection machine is a kind of equipment for manufacturing decorative and functional plastic containers. The manufacturing process of plastic containers begins with the injection molding of preforms, which are unfilled round or spherical metal molds used to make bottles. After the preform is formed, the blow molding machine places the preform into the mold, where it expands and cools to form the final product.

PET BOX INJECTION MACHINE

Pet Box Injection Molding Machine is used to manufacture standard size pet boxes. There are six work rolls and two grooved rolls, driven by a single motor. The speed and strength can be automatically controlled according to the needs to improve production efficiency and quality.

PET INJECTION MACHINE

Pet injection machine can deliver a range of different shots to inject liquid vaccines or medications into your pet. Calibration is quick and easy, with an auto-stop feature that prevents spillage when the cap is removed, and calibrates the next dose. The machine uses heat to relax muscles and reduce inflammation, making it a painless and relaxing treatment.

Daily Necessities Series

(19)PLASTIC COSMETIC PRODUCTS INJECTION MACHINE

Plastic cosmetic products injection machines are used to produce high-quality cosmetics. Including the whole process of fully automatic injection molding, filling and sealing. Stainless steel ink cup is used, which is easy to operate. Good quality, high precision and stable performance. High production efficiency, compared with manual production, the sample production time is shortened by more than half.

PIPE CASTING INJECTION MACHINE

Pipe casting injection molding machine is a highly advanced injection molding machine consisting of hydraulically operated pinch rollers, hydraulic cylinders, hydraulic controls and other accessories. It is used to cast pipes with various precision and required lengths, including pipes, valves and other equipment.

DISPOSABLE CUP INJECTION MACHINE

With the help of injection molding machine, disposable cups can be made at high speed. The machine is made of high quality materials and polished stainless steel. Simply fill the cup, put it into the injection mold, and turn on the machine. It will automatically move back and forth to increase pressure, using special plastic compounds as molding materials to form a protective film at the bottom of the cup. After forming, the formed cups can be taken out from the mold one by one by hand without breaking or cracking.

NYLON CABLE TIE INJECTION MAKING MACHINE

Nylon cable tie injection making machine is a new type of miniature ribbon manufacturing equipment, suitable for the production of cable ties, and can process cable ties with holes, double rings, and multiple rings. It uses a high-speed motor to spin and drive gears. The gear is directly connected with the shaft of the cylinder through the gear reducer, so that it moves back and forth, so as to complete the mixing of raw materials.