Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

Plastic Injection Moulding Machine Manufacturer

Latest Blog

The Comprehensive Guide to Wholesale Servo Mold Injection Machines

In the rapidly evolving world of manufacturing, the efficiency and precision of equipment play a critical role in determining the success of production lines. Among the many machines that have revolutionized the industry, the wholesale servo mold injection machine stands out as a game-changer. This blog aims to provide a comprehensive guide to understanding these machines, their benefits, applications, and how to choose the right one for your needs.

Introduction to Servo Mold Injection Machines

What is a Servo Mold Injection Machine?

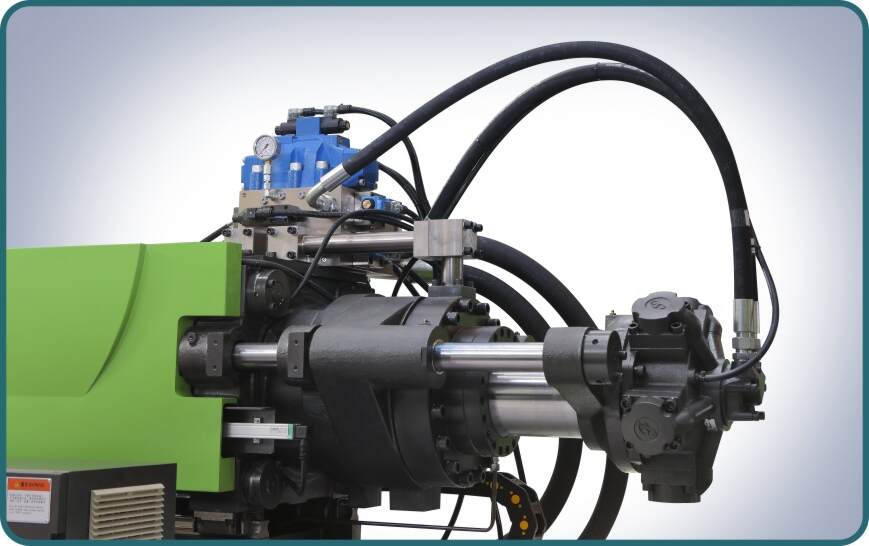

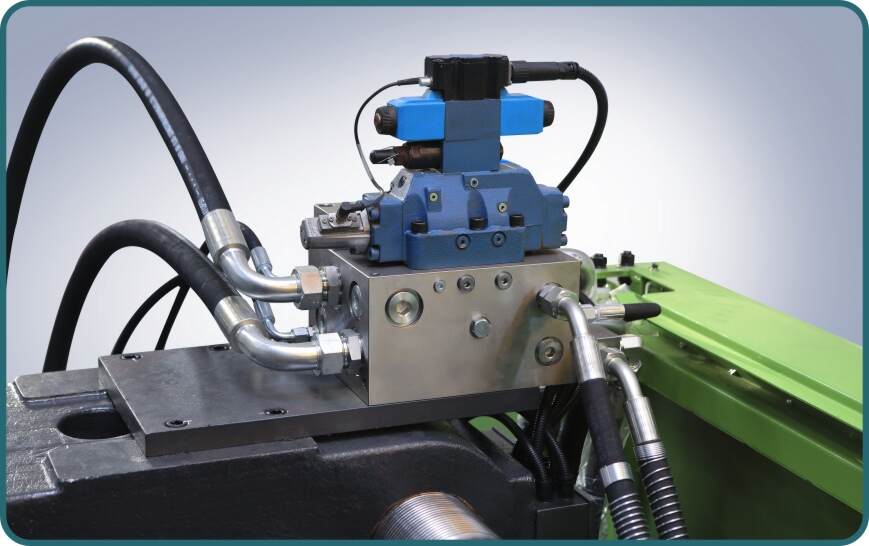

A servo mold injection machine is an advanced type of plastic injection molding machine that uses servo motors to control the various stages of the molding process. Unlike traditional hydraulic injection molding machines, servo-driven machines offer precise control over the injection speed, pressure, and position, resulting in higher quality and more consistent parts.

How Does a Servo Mold Injection Machine Work?

The servo mold injection machine operates by melting plastic pellets and injecting the molten material into a mold cavity. The key stages include clamping, injection, cooling, and ejection. The servo motors provide accurate and repeatable control over these stages, ensuring that each cycle produces parts that meet stringent specifications.

Benefits of Wholesale Servo Mold Injection Machines

Enhanced Precision and Consistency

One of the primary advantages is their ability to produce parts with exceptional precision and consistency. The servo motors allow for fine-tuned control over the injection process, minimizing variations between cycles and ensuring that every part meets the required standards.

Energy Efficiency

Compared to traditional hydraulic machines, the servo mold injection machines are significantly more energy-efficient. The servo motors only consume power when needed, reducing overall energy consumption and operating costs. This efficiency not only lowers production expenses but also supports sustainability initiatives.

Faster Cycle Times

The precise control offered by servo motors allows the servo mold injection machines to achieve faster cycle times. This means that manufacturers can produce more parts in a shorter amount of time, increasing productivity and meeting higher demand without compromising quality.

Reduced Maintenance Costs

The servo mold injection machines typically have fewer moving parts and experience less wear and tear compared to hydraulic machines. This results in lower maintenance costs and less downtime, further enhancing the overall cost-effectiveness of these machines.

Applications of Wholesale Servo Mold Injection Machines

Automotive Industry

The automotive industry heavily relies on the servo mold injection machines for producing a wide range of components, from small clips and fasteners to large body panels. The precision and consistency of these machines ensure that parts fit perfectly and perform reliably in demanding environments.

Medical Device Manufacturing

In the medical device sector, where precision and compliance with stringent standards are crucial, the servo mold injection machines are invaluable. They produce components such as syringes, catheters, and housings for medical equipment with the accuracy needed to meet regulatory requirements.

Consumer Electronics

The production of consumer electronics involves creating intricate and detailed components. The servo mold injection machines provide the necessary precision to manufacture parts for smartphones, laptops, and other gadgets, ensuring high quality and durability.

Packaging Industry

The packaging industry benefits from the high-speed capabilities. These machines can produce large quantities of packaging materials, such as bottles, caps, and containers, efficiently and consistently, meeting the needs of various markets.

Key Features to Consider When Choosing a Wholesale Servo Mold Injection Machine

Clamping Force

The clamping force is a critical parameter that determines the machine's ability to keep the mold closed during injection. When selecting a servo mold injection machine, it is essential to choose one with a clamping force suitable for the size and complexity of the parts you intend to produce.

Injection Capacity

The injection capacity defines the maximum volume of plastic that the machine can inject in one cycle. Depending on your production needs, you should opt for a servo mold injection machine with an injection capacity that matches the size of the parts you are manufacturing.

Precision and Control

Look for a servo mold injection machine that offers advanced control features, such as multi-stage injection, precision temperature control, and programmable logic controllers (PLCs). These features will enable you to achieve the highest levels of accuracy and repeatability.

Energy Efficiency

Given the rising costs of energy, selecting an energy-efficient servo mold injection machine is crucial. Machines with servo motors typically offer better energy savings compared to hydraulic models, making them a more cost-effective choice in the long run.

Reliability and Support

Choose a wholesale servo mold injection machine from a reputable manufacturer known for producing reliable equipment and providing excellent after-sales support. This ensures that you have access to spare parts, technical assistance, and maintenance services when needed.

Case Studies: Success Stories with Wholesale Servo Mold Injection Machines

Automotive Manufacturer Boosts Production Efficiency

An automotive parts manufacturer recently switched to the servo mold injection machines to enhance their production capabilities. The transition led to a 20% increase in output, a 15% reduction in energy costs, and a significant improvement in part quality. The precision and speed of the servo-driven machines allowed the company to meet the growing demand for their products without expanding their production floor space.

Medical Device Company Achieves Regulatory Compliance

A medical device company faced challenges in meeting strict regulatory requirements for their products. By adopting wholesale servo mold injection machines, they were able to achieve the high precision and consistency needed to comply with industry standards. This not only improved their product quality but also reduced the time and cost associated with regulatory approvals.

Consumer Electronics Firm Reduces Manufacturing Costs

A leading consumer electronics firm sought to lower their manufacturing costs while maintaining high-quality standards. By integrating wholesale servo mold injection machines into their production line, they achieved significant cost savings through reduced energy consumption and lower maintenance expenses. The improved efficiency also allowed them to speed up their time-to-market for new products.

Future Trends in Servo Mold Injection Technology

Integration of Industry 4.0

The integration of Industry 4.0 technologies is set to revolutionize the capabilities of wholesale servo mold injection machines. Smart factories equipped with IoT devices, data analytics, and machine learning will enable real-time monitoring and optimization of the injection molding process, leading to even greater efficiencies and higher quality production.

Advances in Material Science

Ongoing research in material science is likely to expand the range of plastics and composites that can be processed by the servo mold injection machines. These advancements will open up new possibilities for creating stronger, lighter, and more durable parts for various industries.

Customization and Flexibility

Future wholesale servo mold injection machines will offer even greater customization and flexibility, allowing manufacturers to easily switch between different molds and materials. This adaptability will be crucial for meeting the diverse and ever-changing demands of the market.

Conclusion

The wholesale servo mold injection machine is a vital asset for modern manufacturing, offering unparalleled precision, efficiency, and cost-effectiveness. Whether you are in the automotive, medical, electronics, or packaging industry, investing in these advanced machines can significantly enhance your production capabilities. By understanding the key features, benefits, and applications of the servo mold injection machines, you can make informed decisions that drive your business forward.