Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

Plastic Injection Moulding Machine Manufacturer

Latest Blog

Wholesale Servo Injection Mold Machine: Revolutionizing Manufacturing Efficiency

In the fast-paced world of manufacturing, efficiency and precision are paramount. The wholesale servo injection mold machine stands at the forefront of this revolution, offering unparalleled benefits to industries ranging from automotive to consumer goods. This article delves into the various aspects of wholesale servo injection mold machines, exploring their advantages, applications, and why they are becoming a crucial asset for manufacturers worldwide.

Understanding Servo Injection Mold Machines

Servo injection mold machines are a type of machinery used in the production of plastic parts through injection molding. Unlike traditional hydraulic machines, these utilize servo motors to drive the injection process, resulting in higher precision and energy efficiency. The wholesale market has seen significant growth as industries seek more sustainable and cost-effective manufacturing solutions.

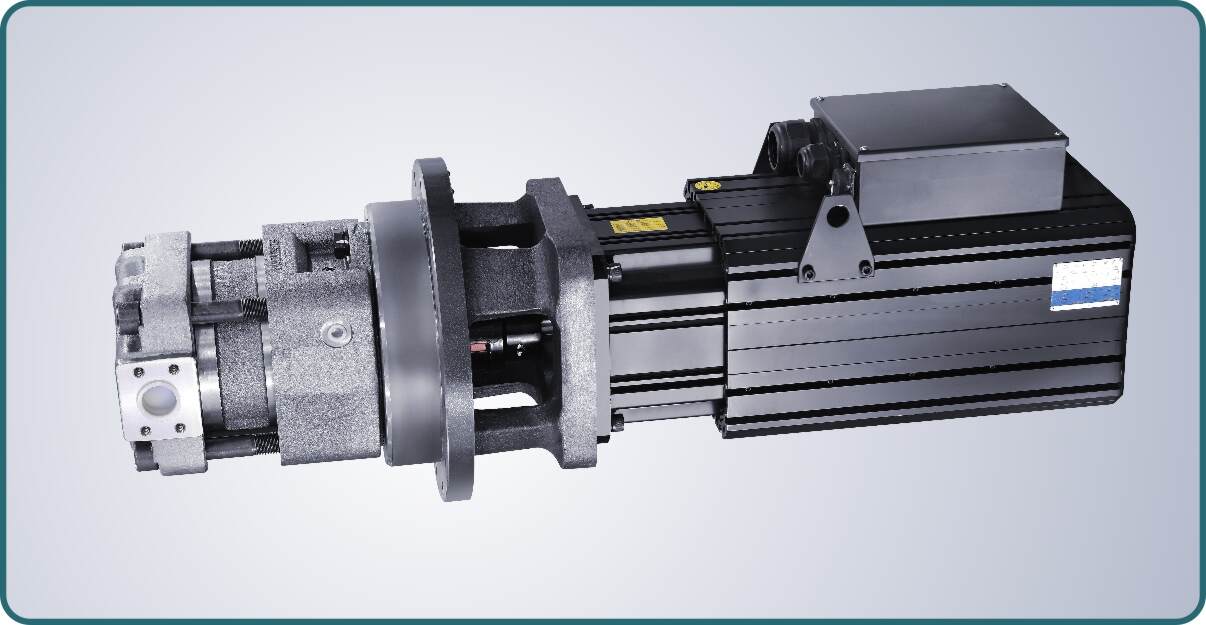

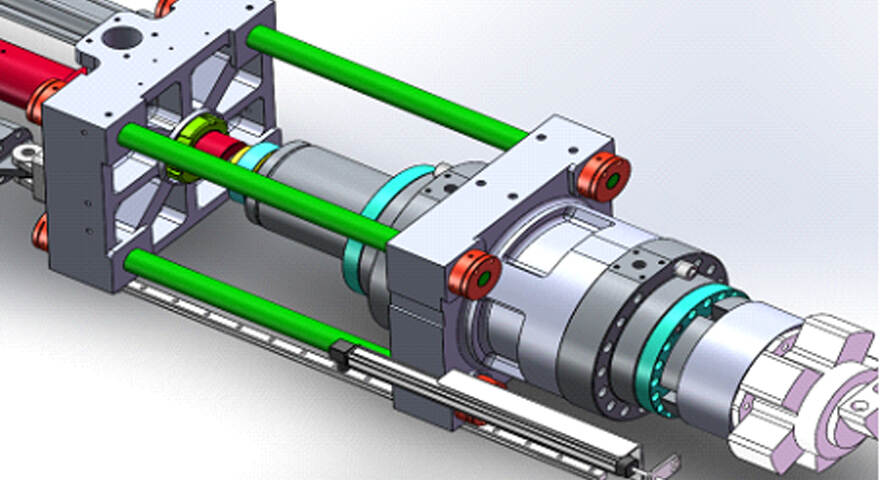

Key Components and Functionality

A typical servo injection mold machine comprises several essential components:

● Servo Motor: Provides precise control over the injection process, ensuring consistent quality.

● Injection Unit: Melts and injects the plastic material into the mold.

● Clamping Unit: Holds the mold in place and applies the necessary pressure during injection.

● Control System: Monitors and adjusts the machine parameters to maintain optimal performance.

The integration of servo motors allows for precise control over the injection speed, pressure, and position, which translates to better quality parts and reduced cycle times.

Advantages of Wholesale Servo Injection Mold Machines

Energy Efficiency

One of the most significant benefits is its energy efficiency. Servo motors consume power only when needed, unlike hydraulic systems that run continuously. This results in substantial energy savings, reducing operational costs and environmental impact.

Enhanced Precision and Consistency

Servo injection mold machines offer superior precision compared to their hydraulic counterparts. The accurate control over injection parameters ensures that each part produced meets stringent quality standards, reducing the need for rework and waste.

Faster Cycle Times

The precise control afforded by servo motors enables faster cycle times. This means that manufacturers can produce more parts in less time, boosting productivity and meeting high-demand schedules without compromising on quality.

Reduced Maintenance Costs

Hydraulic systems are prone to leaks and require frequent maintenance. In contrast, servo injection mold machines have fewer moving parts and do not rely on hydraulic fluid, leading to lower maintenance costs and downtime.

Environmentally Friendly

The reduced energy consumption and lower emissions associated with the injection mold machines make them an environmentally friendly option. As sustainability becomes a critical concern for manufacturers, adopting such technologies helps companies align with global environmental standards.

Applications of Wholesale Servo Injection Mold Machines

Automotive Industry

The automotive industry relies heavily on injection molding for producing various components, including dashboards, bumpers, and interior panels. The high precision and efficiency of the servo injection mold machines make them ideal for this sector, where consistency and quality are non-negotiable.

Consumer Electronics

In the consumer electronics industry, the demand for lightweight and durable plastic parts is ever-increasing. The servo injection mold machines enable manufacturers to produce complex components with tight tolerances, essential for devices like smartphones, laptops, and gaming consoles.

Medical Devices

The medical device industry requires parts that meet stringent regulatory standards. The precision and reliability of servo injection mold machines ensure that medical components, such as syringes, diagnostic equipment, and surgical instruments, are manufactured to the highest quality standards.

Packaging

Injection molding is widely used in the packaging industry for creating bottles, caps, containers, and other packaging materials. The speed and efficiency of the injection mold machines make them perfect for high-volume production, ensuring that packaging manufacturers can meet the growing demand.

Choosing the Right Wholesale Servo Injection Mold Machine

Assessing Your Production Needs

Before investing in a servo injection mold machine, it's crucial to assess your production needs. Consider factors such as the type of parts you manufacture, the required production volume, and the precision needed. This will help you choose a machine with the right specifications to meet your requirements.

Evaluating Machine Specifications

Key specifications to evaluate include clamping force, injection speed, shot size, and mold size. Ensure that the machine you select can handle your production demands without compromising on quality or efficiency.

Considering the Total Cost of Ownership

While the initial investment in a servo injection mold machine may be higher than that of a hydraulic machine, consider the long-term benefits. The energy savings, reduced maintenance costs, and increased productivity often result in a lower total cost of ownership.

Manufacturer Reputation and Support

Choosing a reputable manufacturer is crucial for ensuring the reliability and performance of your servo injection mold machine. Look for manufacturers with a proven track record, comprehensive support services, and positive customer reviews.

Future Trends in Servo Injection Mold Technology

Integration of Industry 4.0

The integration of Industry 4.0 technologies is transforming manufacturing, and servo injection molding is no exception. Smart sensors, IoT connectivity, and advanced data analytics are being incorporated into servo injection mold machines, enabling real-time monitoring and optimization of the production process.

Development of More Efficient Servo Motors

Continuous advancements in servo motor technology are leading to more efficient and powerful machines. These improvements are further enhancing the precision, speed, and energy efficiency of wholesale servo injection mold machines.

Increased Focus on Sustainability

As environmental concerns continue to rise, the focus on sustainability within the injection molding industry is intensifying. Future developments in servo injection mold technology will likely prioritize eco-friendly materials and processes, further reducing the environmental impact of manufacturing.

Conclusion

The wholesale servo injection mold machine is a game-changer in the manufacturing industry, offering unparalleled efficiency, precision, and sustainability. As industries continue to seek innovative solutions to enhance productivity and reduce costs, the adoption of servo injection mold machines is set to grow. By understanding their advantages, applications, and future trends, manufacturers can make informed decisions to stay competitive in an ever-evolving market.

Investing in a wholesale servo injection mold machine is not just about keeping up with technological advancements; it's about embracing a more efficient and sustainable way of manufacturing that meets the demands of today's market while preparing for the future.