Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

PLASTIC COSMETIC PRODUCTS INJECTION MACHINE

Plastic cosmetic products injection machines are used to produce high-quality cosmetics. Including the whole process of fully automatic injection molding, filling and sealing. Stainless steel ink cup is used, which is easy to operate. Good quality, high precision and stable performance. High production efficiency, compared with manual production, the sample production time is shortened by more than half.

PP INJECTION MACHINE

PP injection machine is a kind of injection molding plastic parts designed for injection molding of PP, PE, PVC. Mix the plastic raw materials, adjust the heating furnace to the required temperature, and inject the plastic materials into the mold cavity to mix. Molten plastic pellets are evenly distributed in the mold cavity through flow channels created by core pins or gating tools. After cooling, high-strength, high-density, high-quality plastic products can be obtained.

PIPE CASTING INJECTION MACHINE

Pipe casting injection molding machine is a highly advanced injection molding machine consisting of hydraulically operated pinch rollers, hydraulic cylinders, hydraulic controls and other accessories. It is used to cast pipes with various precision and required lengths, including pipes, valves and other equipment.

DISPOSABLE CUP INJECTION MACHINE

With the help of injection molding machine, disposable cups can be made at high speed. The machine is made of high quality materials and polished stainless steel. Simply fill the cup, put it into the injection mold, and turn on the machine. It will automatically move back and forth to increase pressure, using special plastic compounds as molding materials to form a protective film at the bottom of the cup. After forming, the formed cups can be taken out from the mold one by one by hand without breaking or cracking.

NYLON CABLE TIE INJECTION MAKING MACHINE

Nylon cable tie injection making machine is a new type of miniature ribbon manufacturing equipment, suitable for the production of cable ties, and can process cable ties with holes, double rings, and multiple rings. It uses a high-speed motor to spin and drive gears. The gear is directly connected with the shaft of the cylinder through the gear reducer, so that it moves back and forth, so as to complete the mixing of raw materials.

PVC FITTING MACHINE

PVC laminating machine is a kind of decorative equipment integrating multiple functions. It is mainly used in the manufacture of plastic pipe fittings and valves, and can be used as part of high-end decorations, furniture and curtain accessories, ventilation fans, exhaust fans, kitchen storage boxes and other products. Its main components are: feeding system, cutting system, window opening system. It has good performance in cutting accuracy, smoothness, surface quality and corrosion resistance, and is widely used in hotels, food, industry and other fields.

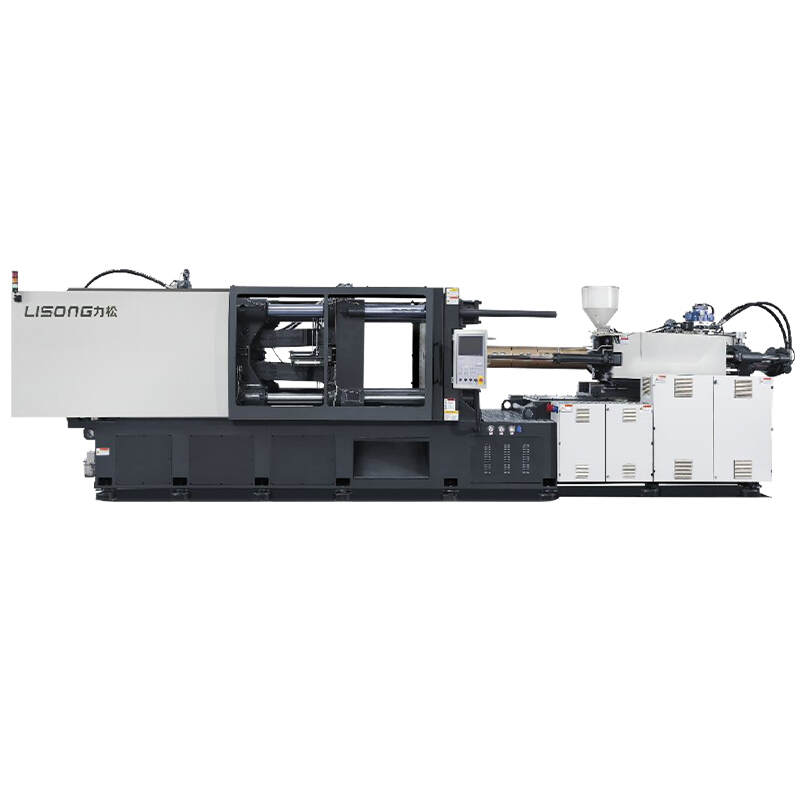

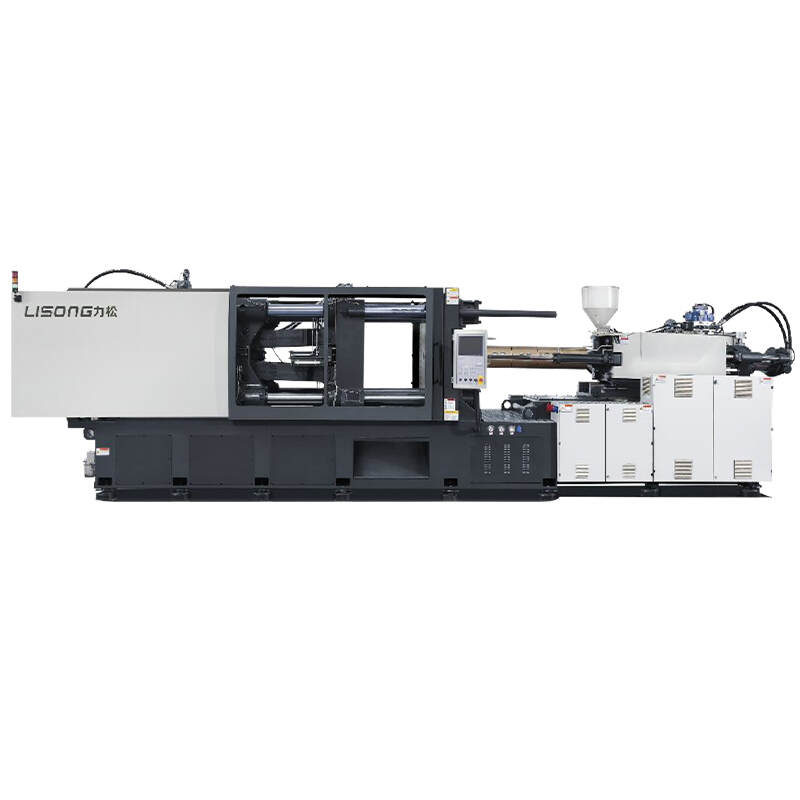

SERVO INJECTION MOLDING MACHINE

The servo injection molding machine is a high-precision, large-cavity, and high-efficiency injection molding machine. Utilize a variety of mold types and materials, including metal, resin, and more. The frequency conversion control system controls the injection pressure to ensure stable injection and high production efficiency. It has the characteristics of accurate positioning, high degree of automation, high efficiency and good quality.

PLASTIC MOLDING MACHINE

Plastic molding machine is the main equipment for plastic injection molding. It uses predetermined temperature and pressure to heat and melt plastic raw materials, and then sends them into the barrel of the tool for injection molding.

BASKET MAKING INJECTION MACHINE

The basket making injection machine is designed for making various lightweight baskets such as straw and paper, and is suitable for general injection molds and plastic products. It can produce brush nets, safety belts, safety nets, sporting goods and other pet products. 3D parts can be made by low-temperature curing injection molding of PUR foam, ordinary foam, closed-cell foam, and sealant.

MEDICAL NEEDLE MAKING MACHINE

Medical needle making machine is used to produce different kinds of medical needles, such as safety needles and skin puncture needles. The medical needle making machine is specially designed for the production of various types of medical needles, such as subcutaneous injection needles and intravenous injection needles, with high precision and convenient operation. It can be widely used in hospitals, medical device factories and other institutions producing medical needles.