Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

INJECTION PLANT MACHINE MEDICAL EQUIPMENTS

The injection machine is a device designed to inject substances into appropriate cavities of the body with very high accuracy. It is mainly used for injection in dermatology and plastic surgery, internal medicine and oncology, orthopedics, dentistry and endoscopy.

MEDICAL DISPOSABLE PRODUCTION INJECTION MACHINE

Medical injection machine is a kind of medical equipment that can automatically inject liquid medicine into the human body. It can connect the whole medical system of hospitals and clinics for medical treatment. High precision and high speed; Compact design, light weight, easy to move.

PLASTIC FOOD PACKAGING CONTAINER MAKING MACHINE

Plastic packaging container manufacturing machine is an advanced production line with simple structure, reasonable design and clear appearance. This machine can produce all kinds of plastic products, such as bean cans, seasoning cans, syrup bottles, seasoning bottles, etc.

CUP INJECTION MACHINE

This cup filling machine is used to fill the contents of different plastic packages, such as bottles and cups. To use the machine, you need to place a suitable plastic container on a threaded screw that is screwed into the top of the filling hopper. Next, you open the clamping plate on the cylinder head so that water pressure can push the plastic into the bottle. Once all containers are full, you can close the splint and then rotate it counterclockwise to remove it from the filling head.

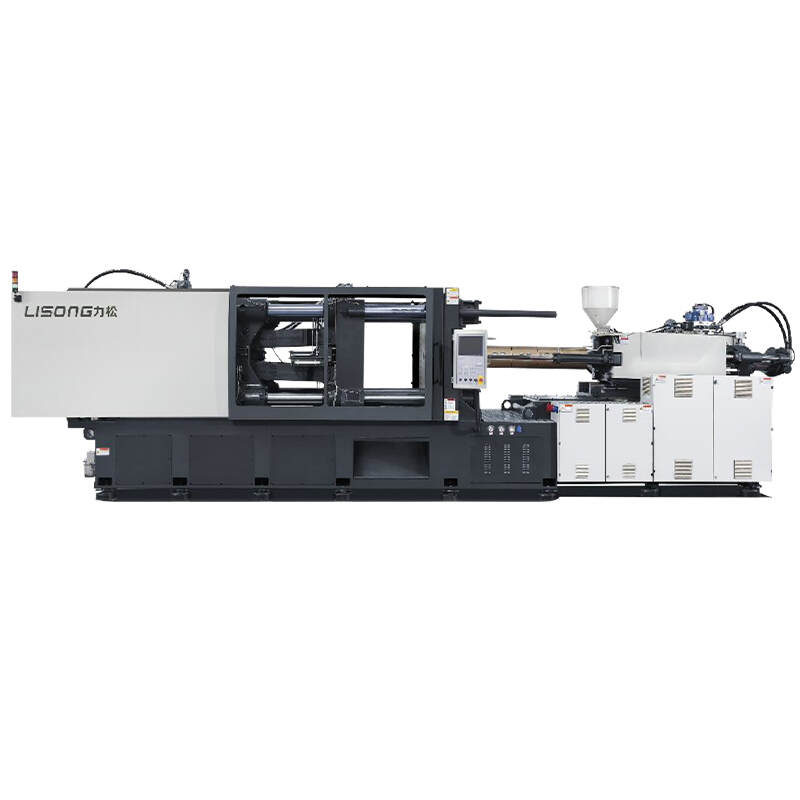

INJECTION MOULD SYSTEM MACHINE

The function of the injection system machine is that in a cycle of the injection molding machine, a certain amount of plastic can be heated and plasticized within a specified time, and then the molten plastic can be injected into the mold cavity through the screw under a certain pressure and speed. . After the injection is completed, the molten material injected into the cavity is kept fixed.

PE CAP INJECTION MACHINE

PE cap injection machine is specially designed for the production of PE, PP pipe caps and connecting joints. It can make bottle caps of various shapes, and continuously injects molten polymer into the mold cavity by pumping. The melt temperature is low, the operation and maintenance are convenient, and it is cost-effective.

BUCKET INJECTION MACHINE

Bucket injection machine inject plastic, glass or metal barrels into the seal. Using standard nozzles allows mixing of different colors and materials, providing mixed color matching capabilities for products. Equipped with a control panel and a safety stop to prevent infusion spillage.

FORK INJECTION MACHINE

Fork injection machines can be divided into linear and rotary. The former generally adopts the rebound type, while the latter is more widely used. The working process of the machine is to use the piston to inject the raw material into the mold of the plastic product, and the processing material heater melts and cools and solidifies to make it shape.

WASTE BIN INJECTION MACHINE

The waste bin injection machine is used to inject waste plastic into empty food packaging materials. The whole production line is composed of main machine, auxiliary machine and energy (mainly electric energy). The main working principle is to use the reciprocating cutter to cut the garbage can into a certain thickness and width, and then press it down by the sliding blade to get the finished product.

CHAIR TABLES INJECTION MOLDING MACHINE

The chair tables injection molding machine is an economical, multi-functional and easy-to-use hand-held injection molding machine, and it is an efficient equipment for completing the injection molding process. Plastic parts can be produced on demand and play a vital role in the manufacture of everything from auto parts to medical devices to household goods.