Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

PACKING INJECTION MACHINE

The INJECTION MACHINE is a fast and effective method of filling and packaging. Ideal for small batch production, the automatic bag-making machine features an advanced injection system that allows for precise filling in seconds. The machine can be used to package meat, vegetables or other types of organic products.

MEDICAL PET BOTTLE INJECTION MACHINE

Medical PET bottle injection machine is a machine that injects liquid into plastic bottles or containers, and can quickly and accurately fill high-viscosity liquids into transparent bottles. It has the characteristics of high efficiency, high precision and energy saving. It has the characteristics of automatic operation, strong adaptability, parameter setting, and excellent plasticizing liquid distribution system. This machine is suitable for single-layer heat sealing equipment for intravenous medicine bottles, infusion bags, and insulin bottles to ensure product safety and tight sealing.

BOWL INJECTION MACHINE

The bowl injection machine is mainly composed of a main body, a driving device, a vacuum cleaner, etc., and is operated manually or electrically through a clutch mechanism. It can be used for bowl filling of snacks, ice cream and desserts. Adopt advanced technology and perfect working condition design to improve the productivity and work efficiency of the kitchen.

PLASTIC SPRAYER PUMP CAP INJECTION MACHINE

Plastic sprayer pump cap injection machine is made of galvanized zinc alloy, stainless steel and plastic. Mainly used in injection molding. With hydrostatic technology, it can be matched with any type of electric drive.

OIL BOTTLE MAKING MACHINE

Oil bottle making machine is used to make bottles of various shapes, such as plastic bottles, glass bottles, etc. Screws are used to inject resin into a metal mold that matches the shape of the plastic you want to make, heat the resulting plastic to bond it together, and pull it out of the mold onto a conveyor belt. Automatic feeding, compression and filling by autoclave and pressure forming, the feeding and packaging system can be modified according to different product requirements.

PLASTIC MOLD DISPOSABLE SPOON

Disposable spoon plastic mold is the most effective and convenient way to make disposable spoons. The production cost is low and the quality is high. The tool is the ideal way to make the perfect plastic spoon quickly! Just pour the liquid into the plastic mold and wait for it to harden. Compatible with any liquid detergent and very easy to use. It's possible to make your own disposable spoons without any extra help.

URINE SPECIMEN CUP MAKING MACHINE

The urine specimen cup making machine is used to manufacture single-use collection containers, designed to produce an accurate number of sample cups with high-quality permanent labels in a short period of time. Used to collect and transport biomedical samples from hospitals/laboratories, purify urine samples for drug testing.

HIGH SPEED 20L BUCKET PAIL MACHINE INJECTION MOLDING MACHINE

High speed 20L bucket pail machine injection molding machine is used for the production of pp/pe packaging containers, and the operation is simple and convenient. When the packaging container is installed on both sides, it will automatically cut off the power supply and other components and continue to work.As a new type of plastic recycling equipment, which can recycle PET industrial wastes, such as bottles, bottle caps, barrel caps, etc.

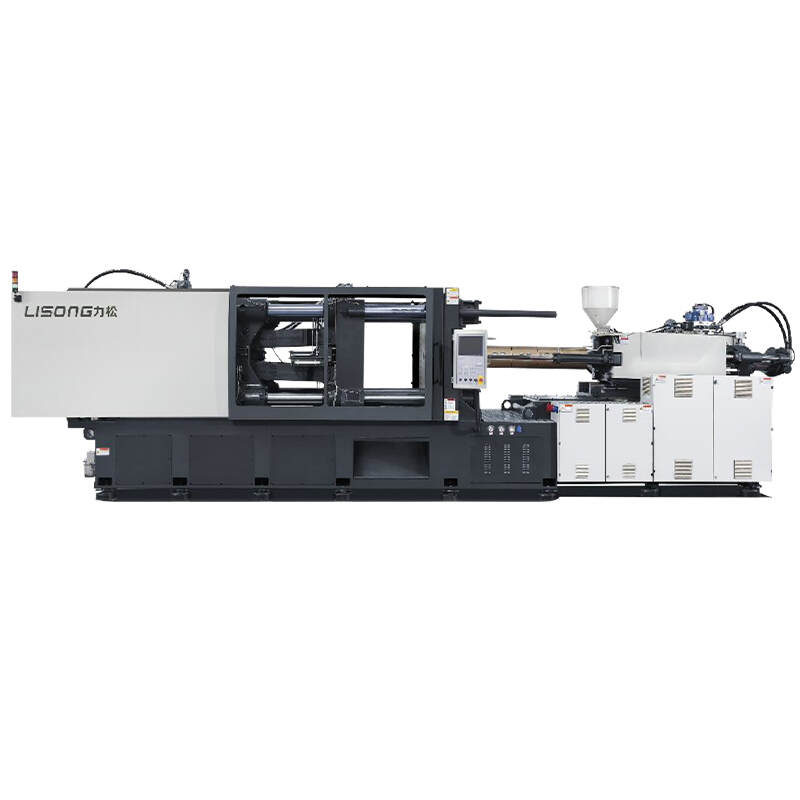

PLASTIC INJECTION MOLDING MACHINE

Injection molding machine - injection molding machine is the main equipment used to perform various plastic processing processes. Polymer manufacturing process usually involves many different machines, which play different roles in injection molding technology. It mainly includes injection molding machine, extruder, heating system, cooling system and metering pump.

IN MOLD LABEL SYSTEM

The in mold custom label system is our most popular custom labeling solution, creating custom labels for a variety of applications, and is a cost-effective solution for printing directly on plastic packaging materials during the molding process.