Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

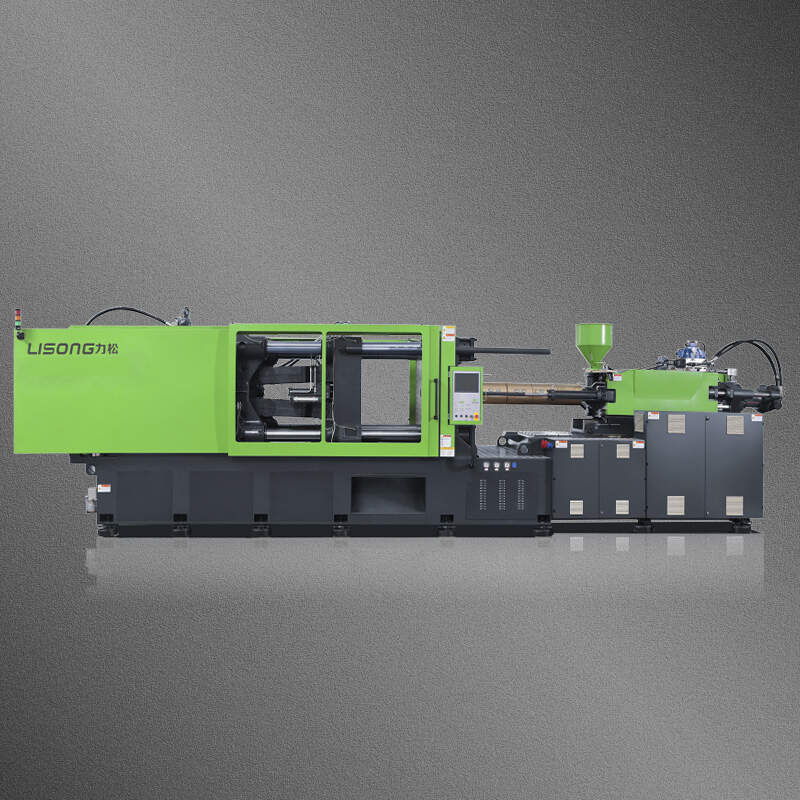

Plastic Injection Moulding Machine Manufacturer

Latest Blog

wholesale injection mold machine for plastic basket manufacturer,supplier,factory for sale

As a mass production of finished products tool, injection molding machine has been widely used in many areas such as automobile manufacturing, home appliance market, smart toys industry and so on. Injection mold machine for plastic basket is only a small type of it. Let's start with the injection mold machine for plastic basket to learn more about this machine.

Types of injection molding

Injection molding is a method of industrial product production modeling. There are two main types of it. They are rubber injection molding and plastic injection molding.

Rubber injection molding

It is a production method of injecting rubber directly from the barrel into the mold for vulcanization. The advantages of rubber injection molding are that the molding cycle is short, although it is an intermittent operation, the production efficiency is high due to the embryo preparation process is canceled, the labor intensity is small and the product quality is excellent.

Plastic injection molding

It is a method of making plastic products. The molten plastic is injected into the plastic product mold by pressure, cooled and molded to obtain all kinds of plastic parts. There is a mechanical injection molding machine specially used for injection molding. At present, the most commonly used plastic is polystyrene。

Benefits of injection molding

Short period

Because the melting plasticization and flow molding of molding materials are carried out in the barrel and mold cavity respectively. It can always be in the state of rapid condensation or crosslinking curing of the melt, which is conducive to shortening the molding cycle.

Mass production

During forming, the mold shall be locked before the melt is injected, and the melt with good fluidity shall be injected into the mold. The wear of the cavity is very small, so a set of molds can produce large quantities of injection molded products.

Low labor requirements

One operator can often manage two or more injection molding machines, especially for automatic unloading of molded parts. More machines can also be managed, so the labor required is relatively low.

Full automation

All molding processes such as mold closing, feeding, plasticization, injection, mold opening and demoulding are completed by injection molding, so that the injection molding process is easy to be fully automated and program control is realized.

Less waste

Molded plastic parts can be used only with a small amount of trimming, and the waste generated in the molding process can be reused. Therefore, there is little waste of raw materials in injection molding.

In conclusion

The emergence of injection molding machines has improved productivity greatly. We can produce many products with quality and quantity guaranteed.

NINGBO LISONG INJECTION MOLDING TECHNOLOGY CO.,LTD is one of the leading wholesale injection mold machine for plastic basket wholesaler and manufacturer and supplier and exporter and factory and exporter in China,welcome to bulk customized buy injection mold machine for plastic basket for sale.