Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

all electric plastic injection molding machine

BOWL INJECTION MACHINE

The bowl injection machine is mainly composed of a main body, a driving device, a vacuum cleaner, etc., and is operated manually or electrically through a clutch mechanism. It can be used for bowl filling of snacks, ice cream and desserts. Adopt advanced technology and perfect working condition design to improve the productivity and work efficiency of the kitchen.

CAP INJECTION MACHINE

This machine adopts motor-driven hydraulic to quickly rotate the cold runner, and cooperates with the hydraulic system to realize high-speed operation, which meets the high-speed filling requirements of soda and water. For the production of caps for pharmaceutical bottles and caps for filling soft drinks, can be designed as wide-mouth bottles and narrow-mouth bottles. The machine has a set of plastic molds. Each mold can hold a different bottle and can produce many different shapes.

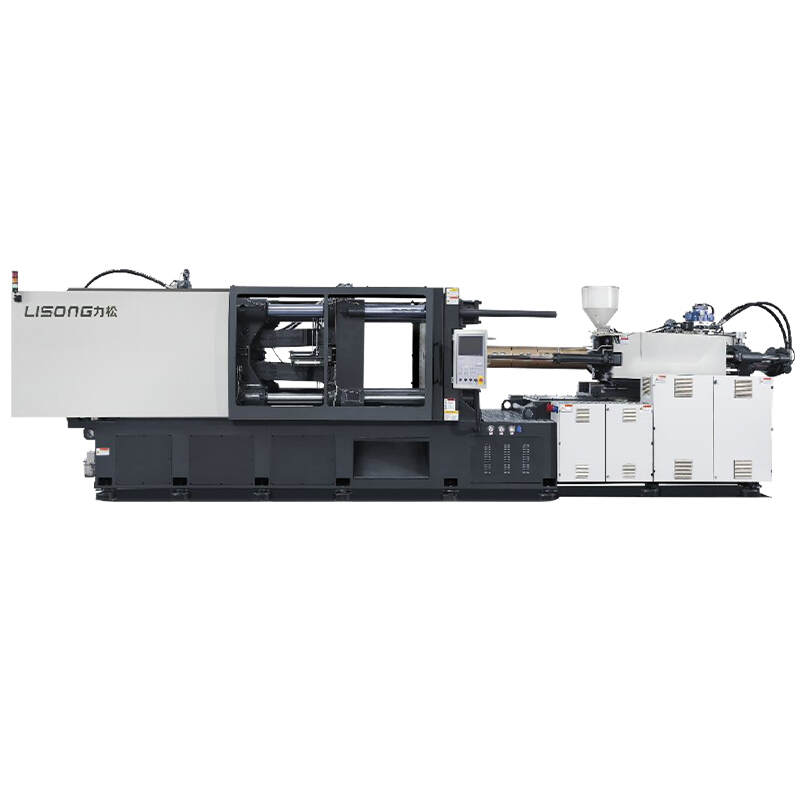

SERVO INJECTION MOLDING MACHINE

The servo injection molding machine is a high-precision, large-cavity, and high-efficiency injection molding machine. Utilize a variety of mold types and materials, including metal, resin, and more. The frequency conversion control system controls the injection pressure to ensure stable injection and high production efficiency. It has the characteristics of accurate positioning, high degree of automation, high efficiency and good quality.

SERVO INJECTION MACHINE

Servo injection molding machine is a kind of comprehensive plastic parts manufacturing equipment with batch processing technology. The servo system drives the whole machine, which can realize continuous feeding, continuous feeding, automatic filling and sealing, automatic weight adjustment, air forming or semi air forming of plastic products. The machine is widely used in food packaging industry.

PVC FITTING MACHINE

PVC laminating machine is a kind of decorative equipment integrating multiple functions. It is mainly used in the manufacture of plastic pipe fittings and valves, and can be used as part of high-end decorations, furniture and curtain accessories, ventilation fans, exhaust fans, kitchen storage boxes and other products. Its main components are: feeding system, cutting system, window opening system. It has good performance in cutting accuracy, smoothness, surface quality and corrosion resistance, and is widely used in hotels, food, industry and other fields.

PLASTIC MOLDING MACHINE

Plastic molding machine is the main equipment for plastic injection molding. It uses predetermined temperature and pressure to heat and melt plastic raw materials, and then sends them into the barrel of the tool for injection molding.