Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

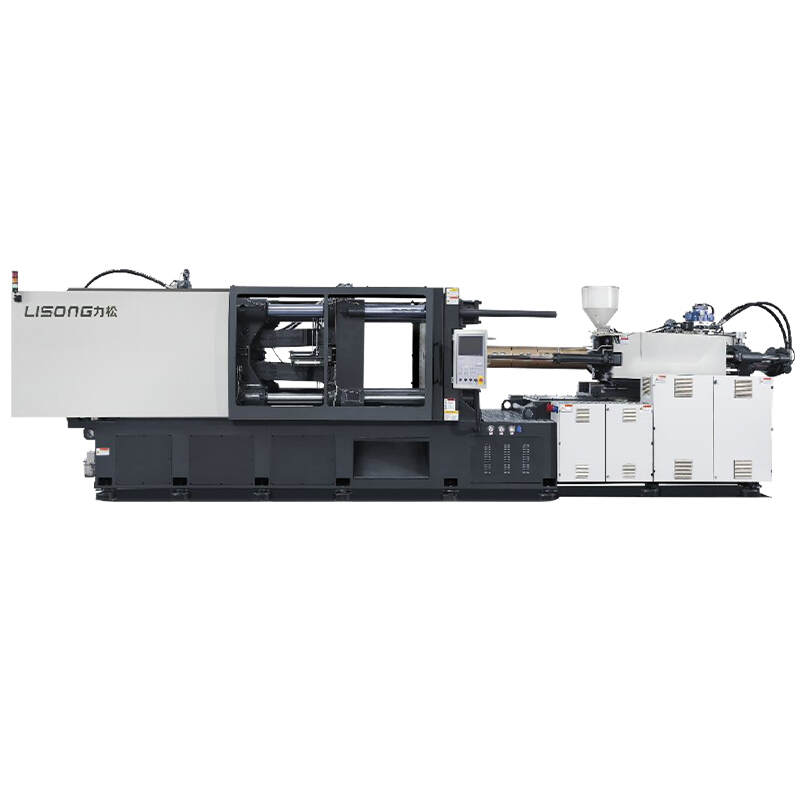

SERVO INJECTION MACHINE

Servo injection molding machine is a kind of comprehensive plastic parts manufacturing equipment with batch processing technology. The servo system drives the whole machine, which can realize continuous feeding, continuous feeding, automatic filling and sealing, automatic weight adjustment, air forming or semi air forming of plastic products. The machine is widely used in food packaging industry.

Produce Details

Place of Origin: China

Brand Name: LISONG

Certification: CE

Payment & Shipping Terms

Minimum Order Quantity:1 set

Packaging Details:container&car

Delivery Time:60 days

Payments: T/T LC

specification

| LS170K | LS220K | LS290K | LS600K | |

|---|---|---|---|---|

| Screw Diameter: | 40mm | 45mm | 55mm | 80mm |

| Screw L/D Ratio: | 22.5L/D | 22.5L/D | 21.8L/D | 22L/D |

| Shot Volume: | 253cm³ | 334cm³ | 618cm³ | 2212cm³ |

| Shot weight: | 230G | 304G | 562G | 2013G |

| injection Rate: | 117g/s | 148g/s | 215g/s | 448g/s |

| Injection Speed: | 366mm/s | 332mm/s | 396mm/s | 516mm/s |

| injection Pressure: | 215Mpa | 210Mpa | 219Mpa | 180Mpa |

| Screw Speed: | 205Rpm | 180Rpm | 215Rpm | 135Rpm |

Product Features

1. High flexibility, simple operation and fast response.

2. Perfectly combined with the production automation system, it is a new molding field with high speed and low energy consumption.

3. Intuitive operation interface and high-definition touch screen display system provide repeat customers with an intelligent memory system of technical parameters.

4. The injection system is automatically controlled and the production efficiency is high.

5. Low energy consumption, high precision and quality.

6. Small size, light weight, easy to move.

Applications

It is suitable for mass production of thousands of sets per day or small batch production of only a few sets.

Suitable for mass production applications in various industries.

For injection in single-cavity or multi-cavity molds.

For filling containers or test tubes

FAQ

Q:What is the processing line of the fully automatic servo injection molding machine?

A:The processing line of the fully automatic servo injection molding machine includes: feeding, weighing and mixing, fluid injection, dispensing, cooling, and packaging.

Q:How to control the servo injection machine?

A:Servo technology uses force sensors to control the speed and position of the outlet, and the speed of each link can be adjusted according to different products. Product quality can be controlled by external equipment through RS485 communication interface.